924 Multi-Filar Coil Winding Machine

The multi-filar coil winder machine uses a camera vision system to wind fine filaments around a spinning mandrel and produce multi-filar micro coils with up-to 4 filars. After the coils are produced, they are used for medical and electronic products, including neurovascular and cardiovascular catheters and electrodes for diagnostic and interventional procedures. Our coil winders are capable of different tensions on each filar enabling our customers to produce micro, multi-filars coils with accuracy and speed.

Coils with multi-filars have different tension, torsion, and stiffness properties. The ability to weave together different material filaments also allows for interesting electrical properties. This makes multifilar coils very popular to use for guiding catheters. The versatility of this machine makes the possibilities endless!

The precise control of all process variables is increasingly important as the material gets smaller. Programmable wind tensions of less than 1 gram and wind angles of less than 1 degree require the use of control systems not previously associated with coil winding. The unique use of machine vision to measure wind angle without touching the filament, and state-of-the-art control systems, make this our most precise machine on the market. The adjustable tailstock allows use of variable-length mandrels.

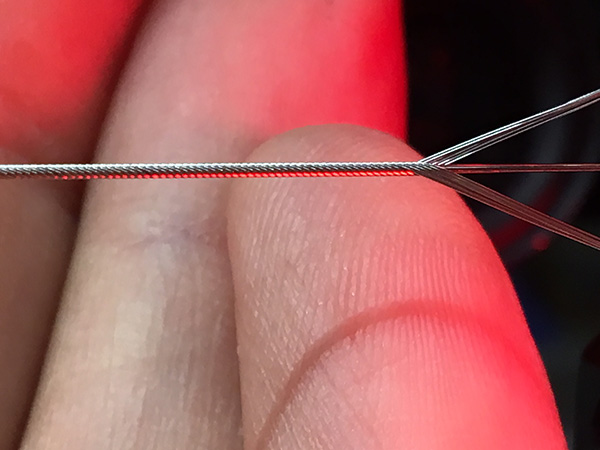

This coil was formed by winding 12 individual .0045″ diameter wires over a .035″ diameter spinning mandrel.

Key Features

Filament .001” to .015” limit travel distance & mandrel length in recipe setting

Filament slack control that maintains tension at all wind speeds

Store up to 250 process recipes shared between two-heads

Brushless servo drives on traverse and both mandrel ends (no back shaft)

DIN 100 filament spool size capable

Recipe edit menu allows up to 30 repeating combinations of any pitch, angle, direction, speed, tension, and length.

Recipe steps can ramp pitch between set points (plus angle ramp with vision option)

Alphanumeric color touchscreen display for program entry and status displays

Specs

- Spool size: DIN 100 maximum

- Input power: 208-240 VAC, single phase with ground, 50/60 Hz.

- Weight: 1,450 pounds

- Dimensions: 167” L x 31” W x 75” H

- Mandrel size: .250 diameter max

- Travel: Adjustable zero to 110” (279 cm) with suitable winding accessories & 2” mandrel stretch

- Filament size: .001” to .015” round solid or tube, or ribbon or metal – 1 to 4 filars per head

- Wind speed: Up to 75 RPS and 10 in/sec traverse speed

- Mandrel tension: Automatically controlled by stepper motor up to 32 kg. Configurable ranges from 45g min up-to 32kg max

- Filament tension: Configurable ranges from 5g min up-to 75g max

- Mandrel length: Adjustable from 21” to 116” (53 to 294 cm)

- Optional angle control: +10°/-30° with +/- 0.02° resolution

- Compliance: Built to CE and NFPA 79 standards