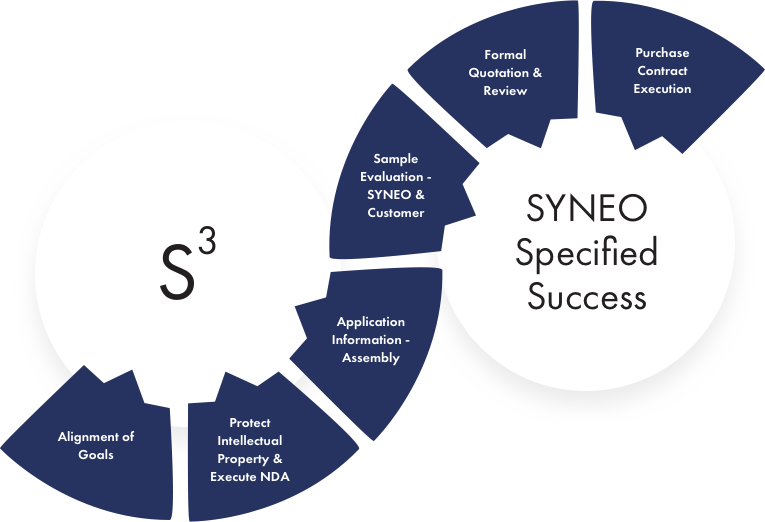

SYNEO Sales & Application Review Process

Born out of demands from printed circuit board and compliant pin connector manufacturers, SYNEO has a long, demonstrated history of listening to customers and tailoring automation solutions and service offerings to solve real customer connector challenges. SYNEO partners with odd-form pick and place equipment manufacturer’s to further automate PCB Assembly manufacturing. SYNEO’S technical team brings over 60+ years of Press-Fit design and manufacturing experience, spanning back to the invention of the electric servo connector press technology.

SYNEO's Sales & Application Review Process

The design and quality of press tooling used to apply force is equally important as the force and resolution by which the force is applied. Draw upon SYNEO’s 60+ years in Press-Fit applications knowledge to get the tooling specified correctly the first time, reducing the risks of costly tooling iterations and additional supply chain management distractions.

STEP 1 | Alignment of Goals

SYNEO begins each application review by gaining a better understanding of our customer’s manufacturing application needs and helping determine exactly what outcome you are trying to achieve. We first focus on aligning your production needs and process flow, and then determine the solution that is required to get there.

STEP 2 | Protect Intellectual Property & Execute NDA

SYNEO approaches every customer relationship with a partnership mentality, establishing a solid foundation of trust and confidence in the protection of intellectual property.

Mutual non-disclosure agreement (NDA) is executed to ensure disclosing and receiving party obligations are clearly defined and intellectual property is protected.

STEP 3 | Application Information - Assembly Drawings, Specifications, etc.

Our customer’s success is dependent on meeting product/process requirements. The exchange of application information such as assembly drawings, user requirement specifications (URS), connector type, PCB dimensions and configurations, tooling needs, operating procedures, videos and photographs – all contribute to expediting the evaluation process and communicating the optimal solution. SYNEO’s application subject matter experts (SME) review this application information and recommend a solution that best meets the customer’s requirements.

STEP 4 | Sample Evaluation - SYNEO & Customer

Customer sample material and supporting manufacturing documentation is provided to SYNEO to allow internal SYNEO applications resources to validate manufacturing assumptions and provide a complete solution, including tooling, if needed. SYNEO is able to provide special tooling, fixtures or software functionality, if needed.

STEP 5 | Formal Quotation & Review

Following customer’s approval, a SYNEO sales team resource will generate a formal quotation outlining a recommended machine, tooling or service solution to meet the needs of the application.

STEP 6 | Purchase Contract Execution

SYNEO’s commitment to your success is sealed with acknowledgement, review and acceptance of the customer purchase order. Let’s get to work